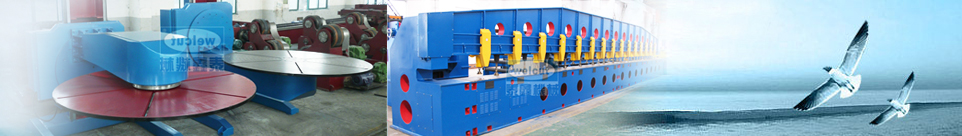

fit up bed rollers(hydraulic fit up)

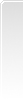

The series of welding manipulator is heavy type, with complete function, easy operation, high automation, which is the idea equipment for improve welding quality and achieving the automatic welding. Integrated with welding turning roll, welding machine, flux transport and recovery machine, with advantages of compact structure, reasonable layout and easy operation. Through proper adjustment, making the seam of workpiece under optimum position, achieving lower the labor strength, improve welding speed and ensure the welding quality.

This LH welding manipulator consists of column, boom , elevation device、guiding device、powered cross inching-adjustment device, powered revolving device, traveling device, people carrying platform, control system etc.

The column elevation rail and boom retraction rail are rectangle type and double rail type.

Boom retraction driving unit adopts motor direct-connect type worm and wheel reducer, drive boom retraction by gear and rack couple;boom elevation adopts two stage worm and wheel reducer driving by chain and sprocket;There is safety device with anti-chain dropping.

Revolving device can lock with pedestal by locking device after Revolving to position

The guiding saddle is equipped with 8 sets of guide pulley for vertical and horizontal movement of boom. The pulley brackets are of eccentric structure. Adjust eccentric shaft of control rollers, the latter contact with rails of boom and column tightly, making smooth travel and elevation of boom without vibration

column revolving adopts slew bearing,with large anti-overturn torque,little clearance in axial and radial direction.

There is platform at the bottom of column for welding power and electric control box etc.

People carrying platform used for monitoring the welding seam and adjust in time, which can guarantee the best quality of welding seam.

Equipment color is WELCUT standard color or specify by client (The client should specify the color code).

According to customer requirement, this equipment can be equipped with flux transportation and recovery system etc function parts for improving the performance

The electrical control in accordance with current nation standard requirements. Electric control system with protection of over current, over heat, over loading, which with locking and self locking protection function for operator safety, which with linkage interface for linkage control of welding turning roll

Welding power is America Lincoln DC-1000 and AC1200, the firm circuit design provide the long time using, whole range output voltage control, simple operation, and accurate output parameters. The output characteristic can be selected. Network voltage compensation, for maintenance the welding stability, allowable fluctuation of network voltage within 10%. The fanner cooling when over load of current and over temperature, self adjust temperature for protection. In humidity and corrosive environment, loop and rectifier with protection. |

English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian